Alaabta

Xirmada birta ah ee fiber-ka ah ama siliga gudaha xudunta u ah dunta ee dunta kulaylka leh

Sharaxaada Alaabta

1-Xirmo ku salaysan fiber bir aan bir lahayn halka dhexroorka fiber kasta uu yahay 12µ ama 14µ. Qadarka fiilooyinku waxay caadi ahaan u dhexeeyaan qiyaastii 200 ilaa in ka badan 1500 fiil. Tani waxay ku siinaysaa adkeysi kaas oo ilaa hadda 'ugu wanaagsan fasalka'. Sababtoo ah fiilooyinka wanaagsan ee la isticmaalo, fiilooyinkani waxay weli yihiin kuwo khafiif ah dhexroorka guud oo sidaas darteed aad u jilicsan marka la farsameeyo.

2- Waxaan daboolnaa tiro balaadhan oo ah iska caabin hoose oo silig ganaax oo dheeraad ah iyo fiilooyinka micro leh dabeecado waara iyo dabacsanaan leh, gaar ah our oo leh dunta gudaha gudaha fiilooyinka micro waxay xaqiijin kartaa caabbinta halkii mitir ee aad u baahan tahay oo ku siinaysa dabacsanaan dheeraad ah ee design laakiin weli waxay ku siinaysaa ka sii fiican. flex-nolosha marka loo eego cu-cable-yada caadiga ah. Iyada oo ku xidhan daawaha dibadda ku duudduubay kaas oo lagu qasacadaysan karo, naxaas, daawaha silver iwm, waxaan soo saari karnaa adkaysi u adkaysta xitaa ka hooseeya 1 ohm/m fiilooyinka micro by hal iyo noocyo go'doonsan sida waafaqsan shuruudaha macaamiisha.

Faa'iidooyinka fiilooyinka micro-core gudaha gudaha ee dharka

Laabashada iska caabinta

Sababtoo ah qaabka iyo isku dhafka walxaha, siligga ayaa leh iska caabin foorarsi oo heer sare ah.

Dabacsanaan

Xadhkaha yaryar waxay isticmaalaan bir bir ah oo dhuuban sida kaari ahaan, taas oo ogaanaysa dabacsanaanta sare.

Ultra-Fine

Ka dib marka la soo saaro fiiladayada yar ee ugu yar waxay noqon kartaa 0.35mm.

Xoogga Xakamaynta Sare

Waxaan isticmaalnaa fiilooyinka Aramid/Liquid Crystal Polymer iyo fiilooyinka tignoolajiyada sare ee iskiis u shaqeya.

Heer sare iska caabin

Waxaan u isticmaalnaa fiilooyinka xidhmada fiber-ka ee birta ah ee aramida ama birta aan taag lahayn ee fiilooyinka, heerkul sare u adkaysta laga bilaabo 230 darajo ilaa 580 darajo doorashadaada.

Dhamaystirka & dahaarka

Adduunyadaada, inta badan waxaa jira baahi loo qabo lacquering gaar ah oo fiilooyinka ama daahan guud extrusion ka badan fiilada dhamaystiran. Waxa kale oo aanu samayn karnaa in, waxyaabaha our extrusion ka mid ah FEP, PFA, PTFE, TPU iwm.

SHARAXA JOOGA CAYDHKA

| Soo saarid | TPE | FEP | MFA |

| Melting Point | 205°C | 255°C | 250°C |

| CShaqada joogtada ah ee Temperature | 165°C | 205°C | 225°C |

Xirmooyinka Fiber-ka ee Bir la'aanta ah

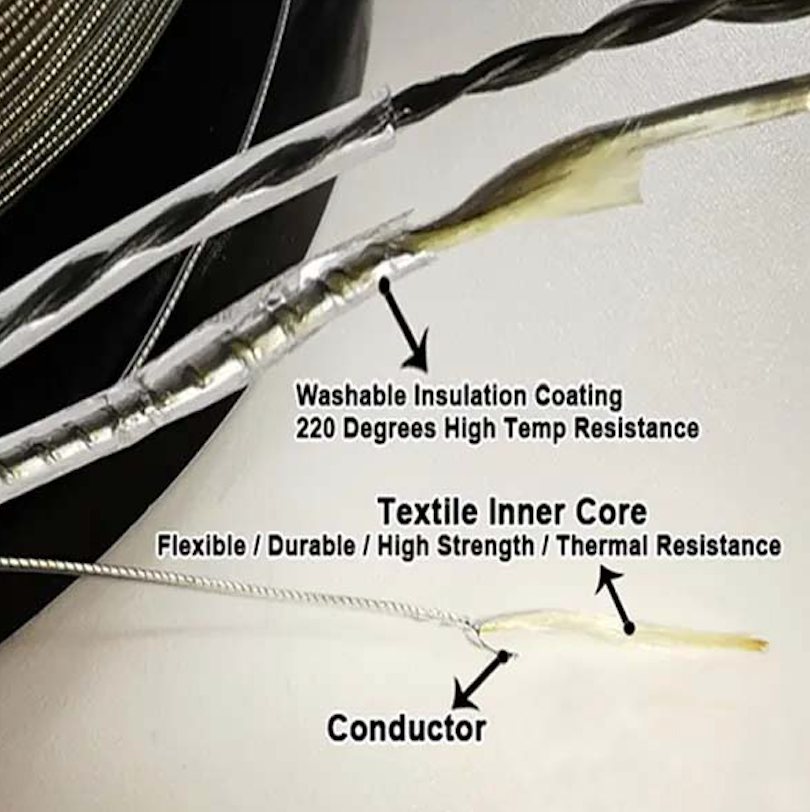

Dharka Gudaha Core Micro Cable Dhismayaasha

Cunsurka Kululaynta Ku Salaysan

Xirmooyinka birta-soo-baxa ah waxay u kala duwan yihiin iska caabbinta tixraacaaga.

| Dhexroorka (um) | Filaments | Xoog (cN) | Miisaanka (g/m) | Kordhinta (%) | Waxqabadka (Ohm/ m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Dharka gudaha ee xudunta u ah siligga is-caabbinta kala duwan

| Hagaajinta Duleedka | Dharka Gudaha Xudunta | Dhexroor mm | Hab-dhaqanka ≤Ω/m |

| Copper 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| Copper 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |

| Copper 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Copper 0.1mm | 200D Dinima | 0.22± 0.02 | 4.00 |

| Copper 0.1mm | 250D Polyester | 1*2/0.28 | 2.00 |

| Copper 0.1mm | 200D Kevlar | 0.22± 0.02 | 4.00 |

| Copper 0.05mm | 50D Polyester | 1*2/0.13 | 8.50 |

| Copper 0.05mm | Polyester 70D | 0.11 ± 0.02 | 12.50 |

| Copper 0.55mm | Polyester 70D | 0.12 ± 0.02 | 12.30 |

| Copper 0.10mm | Cudbi 42S/2 | 0.27±0.03 | 4.20 |

| Copper 0.09mm | 150D Polyester | 0.19±0.02 | 5.50 |

| Copper 0.06mm | 150D Polyester | 0.19±0.02 | 12.50 |

| Tin Copper 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Tin Copper 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| Tin Copper 0.06mm | 130D Kevlar | 0.16 ± 0.02 | 12.50 |

| Tin Copper 0.10mm | 250D Polyester | 0.23±0.02 | 4.00 |

| Tin Copper 0.06mm | 150D Polyester | 0.16 ± 0.02 | 11.6 |

| Tin Copper 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Tin Copper 0.085mm | 150D Polyester | 0.19±0.02 | 6.00 |

| Copper Silver 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |